Technical

1. PRE AND POST INSTALLATION CHECK [ANSI / TPI 1 – SECTION 2.3.4 – REQUIREMENTS OF THE CONTRACTOR]

The contractor shall examine the trusses delivered to the jobsite and examine the trusses after they are erected and installed for:

- Dislodged or missing connectors,

- Cracked, dislodged or broken members, and

- Any other damage that may impair the structural integrity of the truss.

2. TRUSS DAMAGE DISCOVER [ANSI/TPI 1 – SECTION 2.3.4 – REQUIREMENTS OF THE CONTRACTOR]

In the event that damage to a truss is discovered that would likely impair the structural integrity of the truss, the contractor shall:

- Ensure the truss in not erected, or

- If the truss has already been erected, properly shore and support the truss to prevent further damage from occurring and keep the truss free of any load until field repairs have been properly completed.

3. TRUSS DAMAGE RESPONSIBILITY [ANSI/TPI 1 – SECTION 2.3.4 – REQUIREMENTS OF THE CONTRACTOR]

In the event of damage, the contractor shall:

- Contact the truss manufacturer and building designer to determine an adequate repair, and

- Construct the repair in accordance with the written instructions and details provided by the truss manufacturer, building designer and/or any registered design professional.

4. ALTERATIONS TO TRUSSES [IBS – SECTION 2303.4.5 | IRC – SECTIONS R502.11.3 & R802.10.4]

Truss members and components shall not be cut, notched, drilled, spliced or otherwise altered in any way without written concurrence and approval of a registered design professional. Alterations resulting in the addition of loads to any member (example, HVAC equipment, piping, additional roofing, or

insulation, etc.) shall not be permitted without verification that the truss is capable of supporting such additional loading.

5. TRUSS REPAIR [BSCI-B5]

Recommendation to correct damage, jobsite modifications or installation errors.

- Temporarily brace or support the truss to prevent further damage to the truss and danger to the workers.

- Report damage, alterations or installation errors to the truss manufacturer immediately.

- Provide the following information to the truss manufacturer:

- Job Name and/or Number [Available of Truss Tags]

- Truss ID Mark

- Location of the truss on the Truss Placement Diagram, as applicable

- Status of Truss – On ground or installed?

- Type of Damage – Lumber or Connector Plates

- If Lumber, provide location of the damage, dimensions of damage lumber and description of the damage.

- If Connector Plate, provide location of damage, description of damage, joint number(s), size of plates.

- If possible, it is best to mark-up the TDD of the truss(es) that are damaged.

- Photos are very helpful.

- DO NOT attempt to repair the truss without a Truss Repair Design Drawing (TRDD) from the repair designer.

- Prior to beginning the repair, lay the truss on flat or solid, level surface. If the truss is already installed, shore up the truss to relieve any load.

- Repair the truss by following the information provided in the TRDD exactly. Make sure to use the correct materials as specified and fastening materials (glue, nails, screws, etc.)

Seek professional guidance if anything is unclear. - Keep the TRDD in case the building official, building designer or owner request it.

- If the TRDD is not for the specified condition you are repairing, do not use it. Always follow the TRDD prepared for the specific situation.

- If the TRDD cannot be accomplished, inform the repair designer.

Additional Component Resources

Learn more about components at www.bestwaytoframe.com

FRAMING THE AMERICAN DREAM

The Best Way to Frame a House

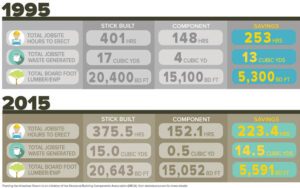

This project overview graphic provides a quick visual representation of the time, labor and waste benefits of using components as well as a more in-depth look into the specific savings in each area based on both the 1995 and 2015 Framing the American Dream studies. This full-page infographic is great to use as a leave-behind with customers or presentation attendees to illustrate the full benefits of framing with components.

This project overview graphic provides a quick visual representation of the time, labor and waste benefits of using components as well as a more in-depth look into the specific savings in each area based on both the 1995 and 2015 Framing the American Dream studies. This full-page infographic is great to use as a leave-behind with customers or presentation attendees to illustrate the full benefits of framing with components.

Floor System Installation

The 2015 Framing the American Dream study was unique in its use of floor panel systems. This infographic looks specifically at the labor savings of installing floor panels versus the floor installation in the stick-built home.

1995 vs. 2015

Data in each Framing the American Dream study, two identical buildings were framed, providing an apples-to-apples comparison of stick and component framing methods. This infographic focuses on what we learned in each area by the numbers.

Data in each Framing the American Dream study, two identical buildings were framed, providing an apples-to-apples comparison of stick and component framing methods. This infographic focuses on what we learned in each area by the numbers.

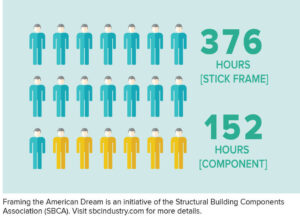

Labor Overview

The results of the Framing the American Dream study looked closely at the total number of hours, broken into discreet framing tasks, to determine how long it took a framing crew to complete each home. This infographic makes the person-hour savings of using components clear at a glance.

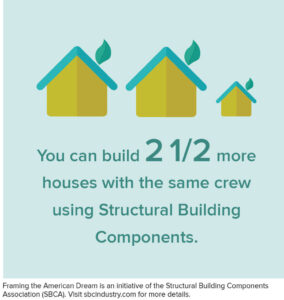

Build More Houses

The Framing the American Dream study shows that a crew can frame two and half homes with structural building components in the time it takes to stick-frame one house.

The Framing the American Dream study shows that a crew can frame two and half homes with structural building components in the time it takes to stick-frame one house.

Create Less Waste

The Framing the American Dream study shows that a stick-framed house creates nearly 30 times more jobsite waste than a component-framed house.

The Framing the American Dream study shows that a stick-framed house creates nearly 30 times more jobsite waste than a component-framed house.

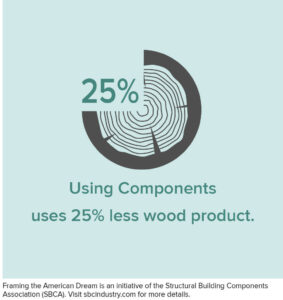

Use Less Wood Product

The Framing the American Dream study shows that it takes 25% less wood product to frame a structure using components. Using Components uses 25% less wood product.

3 Main Messages

This project overview graphic provides a quick visual representation of the labor, waste and material savings of using components, based on findings from the 2015 Framing the American Dream study.

This project overview graphic provides a quick visual representation of the labor, waste and material savings of using components, based on findings from the 2015 Framing the American Dream study.

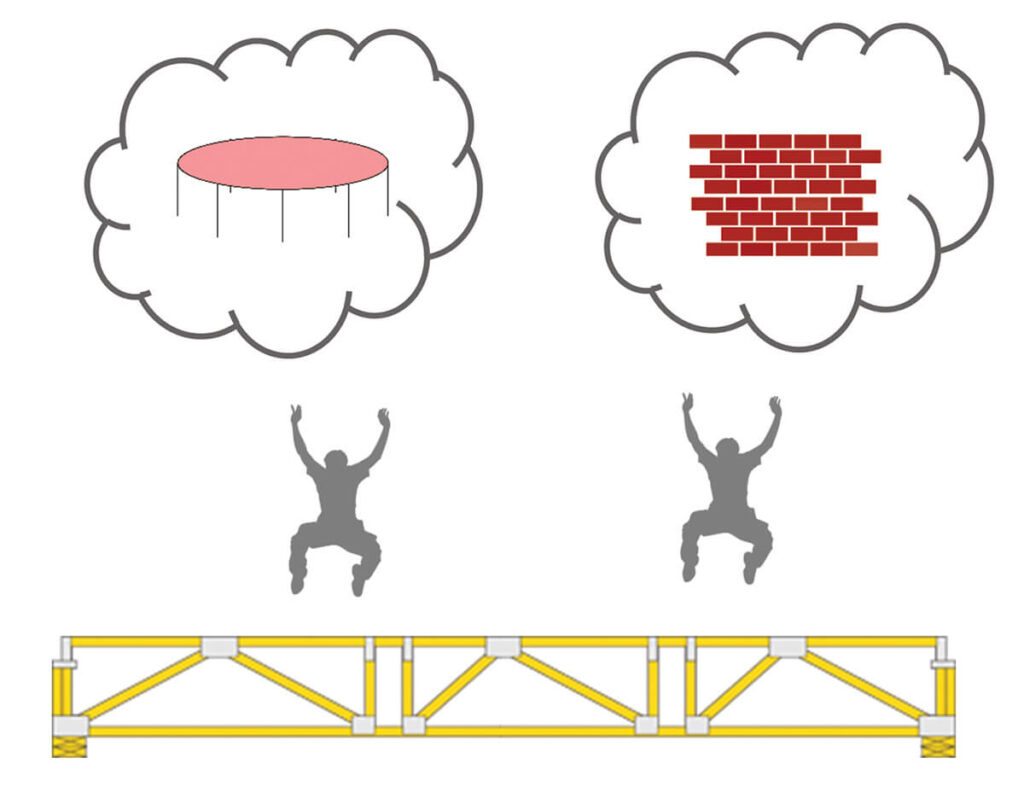

Floor Vibrations: Methods of Control

Gypsum Cracking Issues & Trusses

ASK THE EXPERT

ASK THE BUILDER: FLOOR TRUSS FRAMING

Ask the Builder founder, Tim Carter shows how floor truss framing saves time when installing floor heat tubing.

ASK THE BUILDER: WOOD FLOOR TRUSSES - GREAT ADVANTAGES

Ask the Builder founder, Tim Carter, enthusiastically shares the benefits of building with floor trusses using video taken during the construction of his daughters’ new home.

ASK THE BUILDER: PREFABRICATED WALL PANELS

Ask the Builder expert, Tim Carter, communicates how components expedite the building process and highlights the many reasons to build with wall panels.

ASK THE BUILDER: ATTIC TRUSSES - HUGE ADVANTAGES

Tim Carter, founder of Ask the Builder, shows the simple value proposition of the attic trusses used to create a “bonus room” in what traditionally is wood webs, insulation and dead air.

ASK THE BUILDER: ATTIC TRUSS DESIGN

Ask the Builder expert, Tim Carter, shows off the attic truss design of his daughter’s new home. Tim highlights the benefits of using attic trusses to create more usable space and focuses on how they can be used to construct a regular staircase to the lower level.